Product Parameters

PTDMC Bag Dust Collector Standard Model Selection and Configuration Table

| Model |

Power kw |

Air volume m³/h |

Full pressure Pa |

Bag Quantity ( Only ) |

Filter area ㎡ |

length width height mm |

Weight kg |

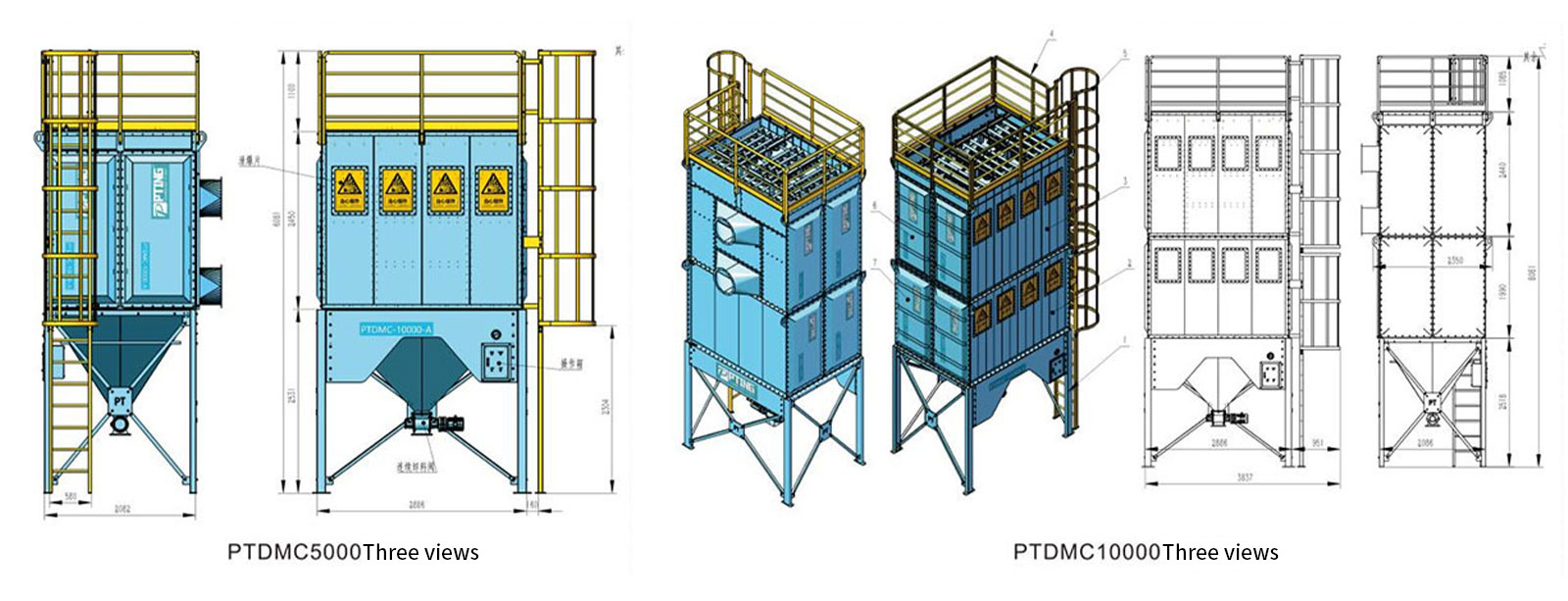

| PTDMC 5000 |

15 |

5000—5800 |

2600-3500 |

112 |

84 |

2500*2210*7250 |

3200 |

| PTDMC 10000 |

22 |

10000—13000 |

2600-3500 |

224 |

168 |

5000 *2210 *7250 |

5200 |

| PTDMC 20000 |

37 |

20000—25000 |

2600-3500 |

336 |

252 |

75000 *2210 *7250 |

6500 |

| PTDMC 30000 |

45 |

30000—36000 |

2600-3500 |

448 |

336 |

10000 *2210 *7250 |

9200 |

| PTDMC 40000 |

55 |

40000—48000 |

2600-3500 |

560 |

420 |

12500 *2210 *7250 |

11500 |

| Based on the size of transportation and installation, more than 30,000 wind stars are assembled in multiple groups or assembled on site |

| optional equipment |

AElectrical explosion-proof B Explosion relief/flameproof disc C Special filter element DCustomized painting F Adapted air duct G Rainproof canopy H Maintenance platform |

*Parameter configuration is subject to modification without prior notice*

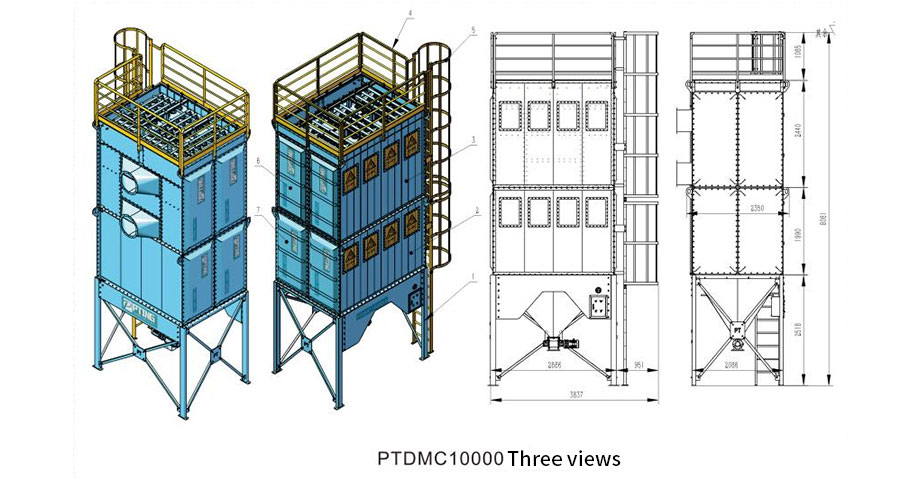

PTDMC series bag dust collector parameter table (single group) equipment technical parameters

1. Filtration area: 84 ㎡; filtration wind speed 0.02 m/s; filtration efficiency: ≥99.95%; ∮133 * L2000 filter bag 84 Pcs

2. Processing air volume: 5000-5800 m3/h; Fan air pressure: full pressure 2600 PA

3. Particulate matter content of clean air end: 4 - 20 mg/m³ (According to filter bag material)

4. Air inlet temperature requirement: lower than 60℃ ~ 250℃ (According to filter bag material)

5. Inlet concentration limit: less than 1500 mg/m3 (The cyclone pretreatment equipment should be added if the concentration is too high)

6. Working resistance: no-load: 20℃ ≈300-600Pa; normal operating 300-1500Pa;

7. Total weight of equipment: 3200 Kg

8. Equipment power: 15 kW

9. Power supply voltage: 380V (AC), 50Hz (GB)

10. Air source pressure: 0.5~0.8 Mpa; flow rate: >2.5 m³/min

11. Noise: less than 72 decibels at a distance of 1 meter (with silencer) (except for interval pulse blowback noise)

12. Dimension: As attached drawings

Equipment manufacturing parameters and electrical component brands

|

Chamber body

|

Q235 ordinary steel; 2-10mm; net weight about 3200 Kg

|

|

|

Surface treatment

|

Powder coating; film thickness 60-120um; PT LOGO (blue)

|

|

|

Pulse valve

|

SBFEC

|

|

|

Display PLC

|

YKHMI

|

Optional

|

|

Centrifugal fan

|

PTING / ROSENBERGER

|

|

|

Switch appliances

|

CHINTZ

|

|

|

Sensing appliances

|

ASMIK

|

|

|

Electric control box

|

PTING

|

|

PTDMC Series Bag Dust Collector Optional Configuration Table

| Configuration |

PTDMC |

| Factory standard configuration items |

|

| 1 |

Equipment body steel structure (carbon steel material) about 3200KG |

● |

| 2 |

Standard coated filter bag and keel D133*L2000*84pcs |

● |

| 3 |

Centrifugal fan RS15KW Q=5000-5800 2600PA |

● |

| 4 |

Standard electrical appliances and pulse control systems |

● |

| 5 |

Electric continuous discharge valve |

● |

| 7 |

Standard parts and assembly hardware |

● |

| 8 |

Surface treatment (spray 60-120um, PT standard color) |

● |

| 2022 market price (Taiwan): 96,000 yuan |

| The following are added or optional items |

| 1 |

Safety guardrail and maintenance ladder |

○ |

| 2 |

Fan to host connecting pipe |

○ |

| 3 |

Cyclone Separator PT/XFT950 |

○ |

| 4 |

Air volume regulating valve DN600 |

○ |

| 5 |

PLC frequency conversion control system |

○ |

| 6 |

84 sets of coated anti-static filter bags |

○ |

| 7 |

Customized equipment paint color or 10-year long-term anti-corrosion coating (C4) |

○ |

| 8 |

Electrical explosion-proof (Exd IIB explosion-proof solenoid valve, explosion-proof electric box, and pipeline) |

◎ |

| 9 |

Body automatic sprinkler system |

◎ |

| 10 |

Explosion-proof and explosion-venting system (explosion-proof, explosion-venting, flame-venting) |

◎ |

| 11 |

Spark detection Pipeline spray Booster pump (2 points 1 spray) |

◎ |

| ● Factory standard configuration ○Optional ◎Explosion-proof and flame-retardant option |

English

English русский

русский Español

Español